The main characteristics of coal-to-liquids industry is the clean use of coal. China’s coal resources are very rich however are relatively scarce in oil resources.

It must be taken as a measure to make full use of domestic coal and develop coal - oil industry in the process of China's economic development.

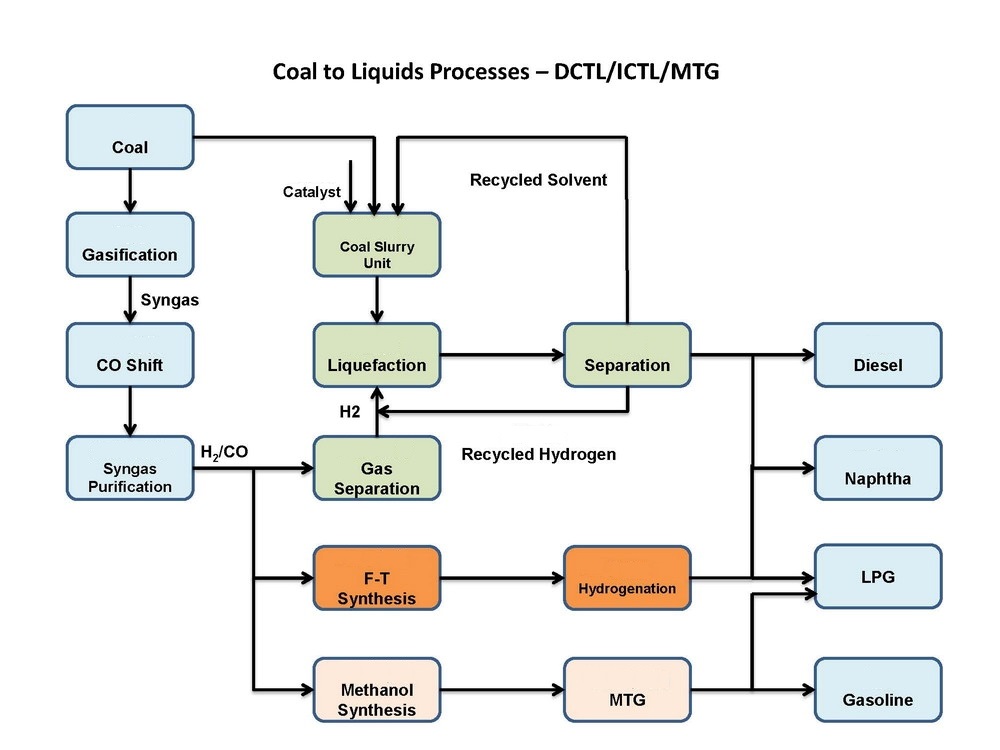

We have a wealth of experience in crushing and drying of coal, coal slurry preparation, liquefaction, solid-liquid separation, gas purification, fractionation and purification of liquid products, as well as liquefaction residue gasification to produce hydrogen and so on.

Besides direct coal-to-liquid fuel (DCTL) and indirect coal-to-liquid fuel (ICTL), as well as the coal-based methanol-to-gasoline (MTG), Coal & Oil Co-Processing is another CTL innovation. Many Chinese and foreign R&D organization has carried out researches on the process during the past decades and achieved a series of progresses, however so far no industrial demonstration plant has ever been installed.

Coal & Oil Co-Processing is to blend coal particles of less than 100μm size with residue oil in a ratio of 1:1, and pass the blend through a hydrogenation bed under 21.3MPa/470℃ and at the presence of pyrrhotite (an iron ore) catalyst. Using the synergism between lignite (or younger bituminous coal) and residue oil, the reaction conditions of DCTL can be dramatically mitigated, and the oil conversion and product yield can be improved. In comparison with conventional DCTL process, co-processing has the advantages of lower hydrogen consumption, lower capital investment and higher conversion rate etc.